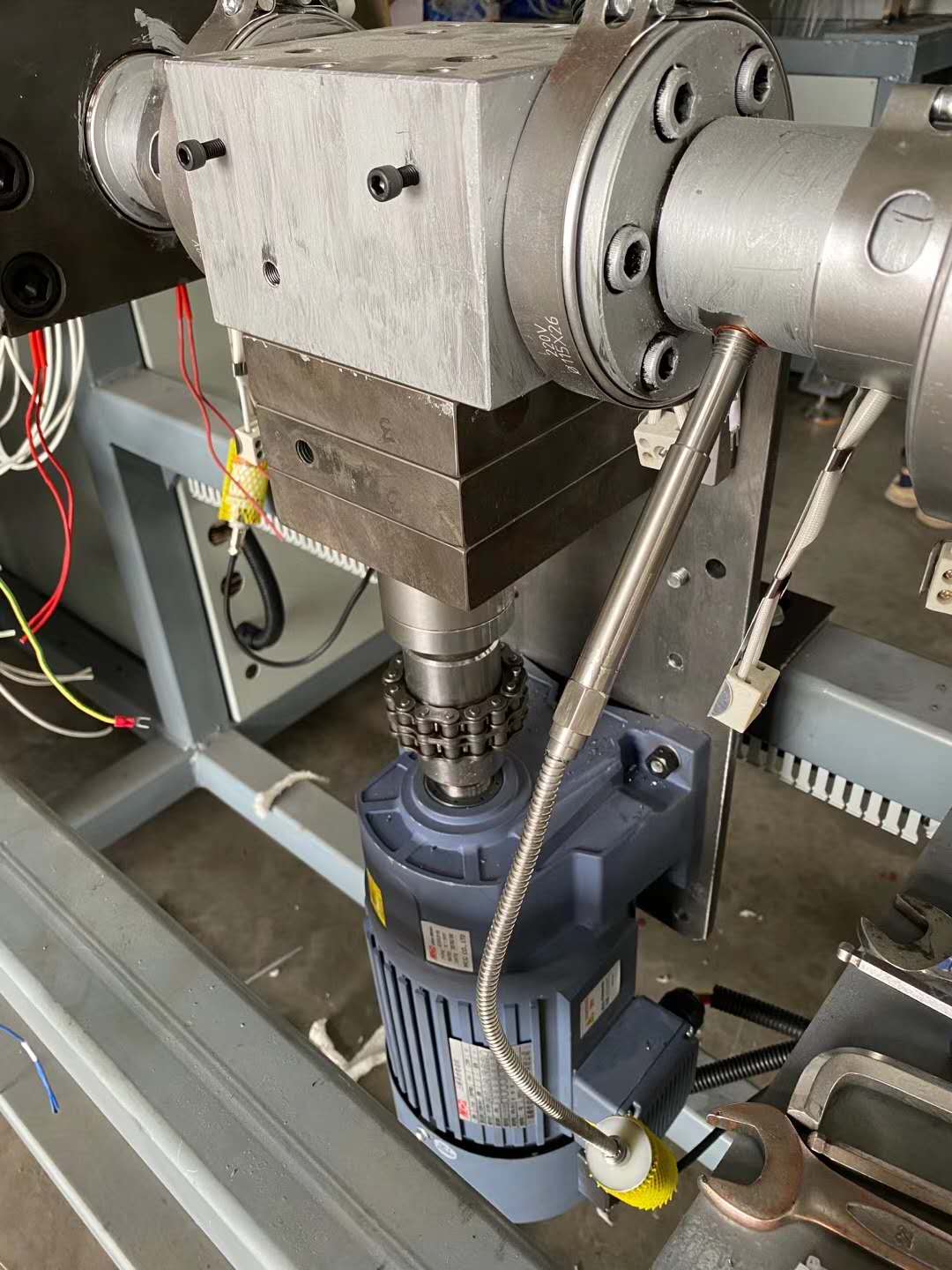

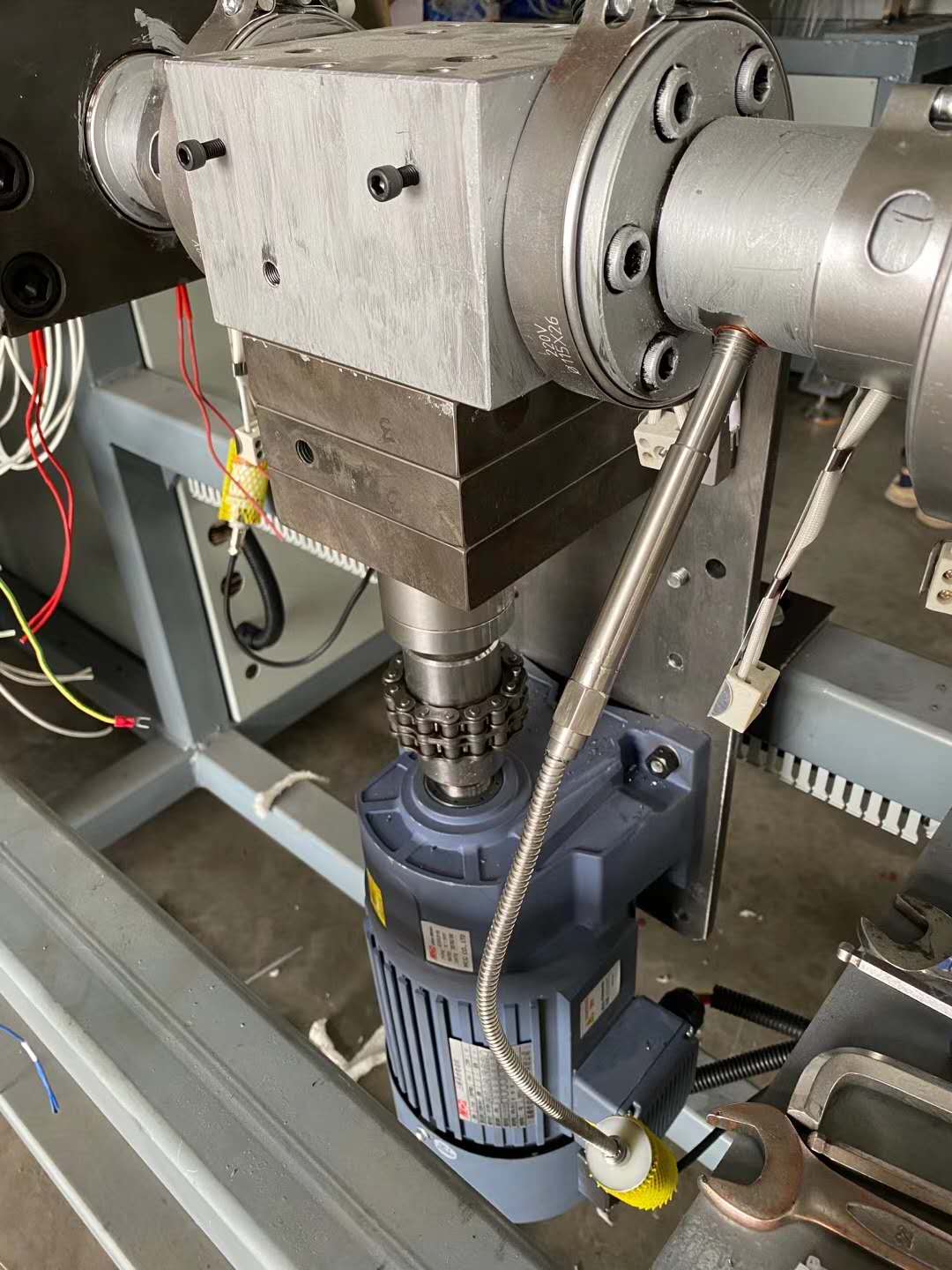

Working principle of gear metering pump

sales01@cxflowmeter.com

The

gear metering pump is a kind of gear pump. Only the gear pump that can deliver accurate and quantitative delivery can be called a gear

dosing pump,

so the gear metering pump has metering characteristics. The gear metering pump is made of precision and process design, selected hard wear-resistant materials,

and processed through special processing. Gear metering pumps began to be used in foreign equipment, followed by imported equipment into the Chinese market.

After years of development, the gear metering pump can stand on the same line with imported products in terms of performance and processing accuracy. And it has

successfully replaced the gear metering pump on some imported equipment, realizing the localization of the product. The following will introduce the working principle

of the gear metering pump.

The gear metering pump is driven by a pair of intermeshing gears, one of which is a driving gear and the other is a passive gear, which is driven by the driving gear to mesh and rotate.

There is a small gap between the gear and the casing of the pump. When the gear rotates, in the suction chamber where the gear teeth gradually disengage, the closed volume between

the teeth increases, forming a partial vacuum, and the liquid is sucked into the suction chamber under the action of the pressure difference. It is pushed forward by the gear between it and

the casing, and sent to the liquid discharge chamber. In the liquid discharge chamber, the two gears are gradually meshed, the volume is reduced, and the liquid between the gears is squeezed to the liquid discharge port.

Because the machining accuracy of the gear metering pump is very high, whether it is the tooth surface accuracy of the gear, or the matching accuracy of the gear and the casing,

the gear and the tooth top are very high, so the gear metering pump has a certain rotational displacement. In other words, every time the gear rotates, the volume of the liquid

discharged is constant, so as the speed of the gear metering pump is adjusted, the gear metering pump can discharge a corresponding amount of liquid. By measuring the rotational

speed of the gear metering pump, the flow rate of the gear metering pump is obtained.

The above is the working principle of the gear metering pump, If you want to know what kind of metering pump you need in your current working conditions,

which one of our

metering pumps is most suitable for you, please contact winny:

sales01@cxflowmeter.com